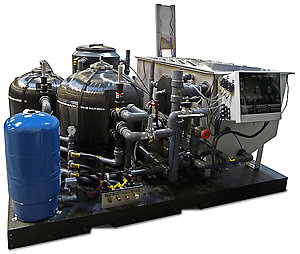

Mi-T-M Biological Water Treatment Systems

A clarifier allows for greater settling and removal of accumulated solids in wastewater before treatment. This pretreatment makes it easier for water treatment systems to operate effectively.

- Cone-shaped tank for easy handling of accumulated solids.

- Quality recycled wash water without common odor problems

- Easy operation and maintenance

- Easily accessible pumps

- ETL listed control panel

- Heavy-duty, corrosive-resistant and UV-resistant poly-skid