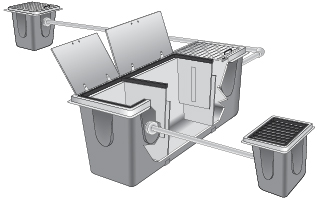

Water Maze High Boy Adaptable Filtration

The Water Maze Indexing Polishing Filter (IPF) solids unit utilizes inexpensive fabric media to filter out solids. Filter fabric, which is supplied in 5, 20, and 50 micron sizes, is automatically indexed onto a recessed conveyor belt constructed of a high tensile, non-corrosive material. As water and solid particles drain through the filter fabric, solids are retained. As the water level rises, a float will actuate a drive motor and the conveyer belt will index the spent paper and new paper replace it.

Can be used as pretreatment or post treatment to another water treatment technology to remove particulates or as a standalone treatment system.

- Carbon steel exterior with a stainless steel interior.

- Exterior mounted drive motor with a covered housing.

- Includes a collection container for spent paper and sludge.

- 82-gallon tub included.

- Optional discharge pump available.