Sioux SF-3.8E All-Electric Steam-Flo® & Sioux Barrel Steaming Tool

- Complete clean — steam expands inside the barrel to clean all surfaces

- Penetrates the wood — pulls out stains, removes tartrates, and kills pathogens

- Uses less water — only use 1-3 gallons per barrel

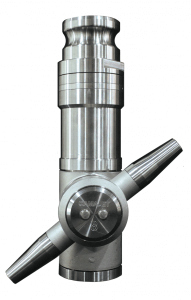

Sioux’s innovative portable barrel cleaning steam generator and barrel steaming tool provides wineries with the most thorough and efficient steam cleaning of multiple barrels. Steam opens the pores for a more thorough and deep clean. Steam also rehydrates the barrel staves, swelling and sealing the barrel, to allow continued use and extending its lifespan. The stainless-steel barrel steaming tool is a universal mounted, self-aligning tool with spring-loaded axial bung cone to compensate for various barrel and bung hole sizes which creates the best possible seal for greater efficiency and safer steaming and dual steam outlets for simultaneous barrel steaming.

SF3.8E All-Electric Steam-Flo®:

- 38 KW Electric Heating Element | 3.8 Boiler HP | 133 Lbs./Hour Steam Output for multiple barrels

- 15 PSI Maximum Operating Pressure with adjustable pressure switch

- 250F maximum outlet temperature | 480V/3PH/60Hz Operating current 46 amps

- Includes inlet water feeder with flow valve, low water level switch, high limit pressure switch with manual reset

- ASME rated pressure relief valve | Two - 1” MNPT Steam Outlets | NEMA 4X watertight main electrical enclosure

- Polished stainless-steel enclosure with removable access panels | Easy-rolling caster mounted for ease of portability